|

|

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

C: Circuits for advanced users –

Automation of Processes C1: My view concerning the

term “ANALOG” |

|

Translated from German by Axel Wurl, later

extended by Herbert Otto The reason for establishing my

exclusively German-speaking Facebook group was the constant

attempts by digital railroaders in other groups to proselytize us

conventional (analog) operators: “digitally, everything is possible …” The thought, the idea, the feeling

that whatever would be possible digitally should actually also be feasible by

conventional means then gave me another reason to bring that community into

being. It soon showed, though, that a

multitude of members would rather need help with the basics than aim at

automated operation. This prompted the development of the series of articles

in the section “The very first basic knowledge about conventional controlled Märklin H0

model railways”. The idea to carry automation by

electromechanical means to extremes, step by step, and to illustrate the

possibilities as clearly and elaborately as possible has been my aim ever

since and is being covered in the section “Circuits for advanced users – automation of operations”.

There have been differences of

opinion about what kinds of operation aids may be discussed in my group. I am

describing and justifying the limits of tolerance within my group and this –

my – site in the treatise. Märklin HO ... : Every product that can be used

within the Märklin H0 system is of interest to us, thus,

... analog control and operation (from my group’s name) And here the problems begin... When what is commonly understood by

digital control of model trains first appeared on the market, “analog” was

chosen as a simple synonym for “not digital”, usually ignoring the fact,

though, that between black and white, digital and analog, there are countless

shades of gray. Digital,

in the sense, refers to model railroad products that communicate by means of

encoded control signals sent simultaneously to a multitude of

ready-to-receive devices as an encoded pulse sequence through a two-core wire,

and the device addressed by this encoded control signal decodes it and then

performs the respective command. Analog, accordingly, refers to control

signals, or better: control voltages, sent directly from the control unit,

through a multitude of wires, to each individual device, without encoding and

the necessary hard- and software. The differences of opinion I

mentioned before are fueled by the conventional (analog?) appliances, and

especially by the combination of such on a larger scale, and the use of

electronic aids. I will come back to this later on. The supposedly knowledgeable model train

enthusiast may find this trivial, but in case of disputes, I will refer to

the definitions in this treatise. In order for a clear picture to evolve, it

is necessary for me to split hairs. The definition of “analog”: Some synonyms for analog are:

The definition of “analog signal”:

An example of truly analog devices supposedly everybody knows: The kitchen or bathroom scale.

Both mechanical and electronic versions are available.

A spring is tensioned by the weight

force applied, and a hand displays the deflection on a scale with a pointer -

continuously, steadily, stepless! Some electronic scales (right) are controlled

digitally. They measure the weight by means of

electronic sensors at regular intervals and show the values at these

intervals, rounded, on a digital display. Scales which such behavior do NOT

work continuously, NOR steadily, NOR stepless.

(picture source: themt.de) What do you see

before your mind’s eye when you think of an

conventional, “analog” model train?

(Transformer

here signifies a control device with a turning knob or handle that allows

adjustment of the output voltage.) Heretic question: Is a Märklin transformer really “analog”? Continuous, steady, stepless? My answer is NO! Slowly turning the knob or handle to

the right, at first, nothing happens. With a measuring device (voltage

meter), we will see that the output voltage is still zero volts. The pickup finger inside the

transformer, mounted to the turning knob, is not touching the live secondary

coil yet, thus the output voltage is not continuous. Only after turning the knob by a few

degrees, the lights in the traction vehicle begins to shine. The measuring

device will show a low voltage, between some four and eight volts, depending

on the transformer; this is not stepless,

but a sudden increase, or jump, from 0 to 4 – 8 volts. Continuing to slowly turn the knob,

the lights will shine a little brighter, but the traction vehicle will not

move yet. In some circumstances, while turning the

knob, you may feel something like a slight vibration (at least with older

transformers), as if there were a very fine bar grid. This is caused by the

mechanical construction of the voltage pickup finger inside the transformer.

The secondary coil, which supplies the voltages usable for the model train,

consists of very tightly wound copper wire, covered with insulating enamel.

The slight vibration you may feel are caused by the

pickup finger briefly getting caught in the tiny gaps between the windings.

Neighboring windings have a slightly different voltage. Moving the pickup

finger over the secondary coil, the large number of windings results in a quasi-analog change

in voltage, not steady, but in tiny steps.

So, if you are very finicky, the output voltage

of a Märklin transformer is not continuous, not stepless, and not steady, and

thus, by definition, not analog. The same can be seen with the

prototype: speed and power output, at least in older electric locomotives,

are controlled in steps, since a purely analog control was (is?) not

technically feasible. Continuing to slowly turn the knob, you

will hear a hum from the motor even before it develops the power necessary to

overcome the resistance of the transmission. What you hear is the 50 Hertz of

the alternating current you are using. Further turning the knob slowly will set

the vehicle in motion, but at a greater speed than expected or hoped for, not stepless. You can now turn the knob back a little,

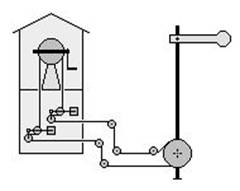

and the vehicle will continue moving. Back to our initial question: 2nd: You will need railroad

tracks, which, unless they form a simple oval, are often electrically

separated into various sections. These sections are or can be assigned to

separate transformers. 3rd: You may have a variety

of control panels and switchboards for manually operating turnouts, signals,

uncoupling track units, illumination, etc. Every command signal is sent to

the individual device separately through individual wires. Trains are driven by manually regulating the

speed, turnouts and signals

are set as desired, dependencies, often observed halfheartedly at best, are

stored in the head of the user. “Regulating” refers to modifying the correcting

variable depending on the feedback from the result of the command. With a manually regulated model

train, this means adjusting the factual speed of the train by hand, based on

the individual impression. “Controlling” only means activating or

deactivating a function without feedback. The transformer is

a control unit, while the combination of human plus transformer,

hand-eye coordination, is regulation.

Automatic regulation by analog means

is possible, (example: the flyball governor of a steam engine,) but hardly

feasible in a vehicle of such a small scale. Driving along a track oval, you may

notice that at a certain distance from the feed-in, the train slows down

somewhat, to become faster again as it gets closer to the feed-in again. Reason: the transition resistance

between track pieces accumulates, lowering the voltage with each connector.

With an analog measuring device, this is difficult to measure, unless you

have one that is very good and thus very expensive. Here, we have one of the

advantages of digital measuring technology. If we lay tracks across a hill, the

vehicle will slow down driving uphill, accelerating when going downhill. Finding: the speed

of an conventionally controlled vehicle is

influenced by the driveway. In conclusion, you may say: The manual operation of a model train “feels analog”. Automation of functions by conventional means

(my objective) Even on a small layout, running two

trains simultaneously without accidents requires a certain amount of

concentration. That is why Märklin has thought up and published ideas for

automation early on and has equipped signals with the necessary switching

contacts. The basic idea behind founding the

group was to raise awareness for these possibilities, make practical use of

them, refine them, and carry them to extremes.

I have heard it said that since

relays know only “on” and “off”, 0 and 1, they were digital. Would that mean

the Märklin universal remote control is a digital component? What, then, with

turnouts and signals, which work the same way? That would also mean: Only when a button is pushed

manually, and the circuit, thus closed, activates the solenoid coil, changing

the signal aspect, this would be “analog”, conventional. If a vehicle drives over a contact

track, thus closing the circuit with the same result, this would be process

control, thus digital, even more so if other relays, forming dependencies

like turnout directions and track occupancy were part of the circuit. So, if we want to achieve automation

with relays, we have to wave the term analog

goodbye, but must NOT use the term digital

either. Märklin calls it conventional.

I am calling it also electromechanical and in my sense, the sense of the group and this

homepage. The 1955 Märklin signal booklet describes

several versions of block signaling controls, with contact tracks and double coil signals, and automatic

train running control. Back in the day, the average model train enthusiast

knew nothing else and would thus not have used the term analog, let alone digital. I consider a block signaling control,

only consisting of trainoperated contacts and electrically switched signals

to be electromechanical and in my sense and thus in the sense of the

group, and this homepage. The electromechanical control of a

station on a single-track line, on which trains automatically meet without

colliding, I consider to be in my sense

and thus in the sense of my group and this homepage. The electromechanical control of a

hidden fiddle yard with quite a few tracks, in which the arriving train

automatically starts the neighboring next unit, I consider to be in my sense and therefore in the

sense of my group and this homepage. Also, the manual operation of

turnouts and signals can be simplified by smartly designed circuits and the

use of relays, the number of buttons to be operated can be drastically

reduced. As an example I would like to mention the relay switch towers of the

Deutsche Bahn. Hardly anyone would think of calling these digital. So I also

consider circuits in this scope as in my sense

and therefore in the sense of my group and this homepage. If a model railroader has his layout

controlled by cabinets full of relays, with telephone dials and the like, we

would like to see that in my group and I consider that in my

sense and therefore in the sense of my group

and this homepage. Semiconductors are common in

conventional model railroad layouts. Without diodes and transistors, many

things would be impossible or difficult to do. We need them, so they are

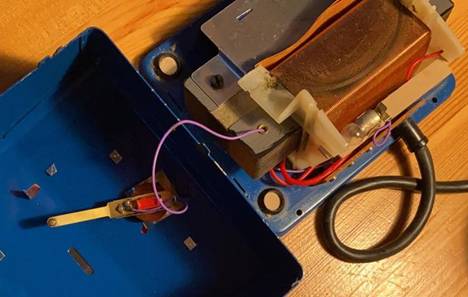

permissible. Electronic components of well-known

manufacturers which are built up using semiconductor elements and relays,

e.g. for smooth starting and braking by appropriate control of the traction

voltage or (superfluously) for the fiddle yard control or the block control

or the electronic universal remote switch 7244 or ... or ... I consider to be

in my sense and thus in the sense of my group and this homepage. Activating a turnout with a servo

drive, if the drive with its control is considered as a functional unit and

is set straight and branching via two switching contacts, I consider as in my sense and thus in the sense of my group

and this homepage. Analogously, this applies to signals moved with

servo drives, shed gates, turntables, animated figures, etc. The inner (digital) structure of a functional unit

is basically of no interest to us if the unit acts from and to the outside

like an electromechanical device, one could also build it

electromechanically, albeit with immensely greater effort. Control

centers The larger the layout becomes, the

more drives have to be moved, the more complicated the interrelationships

become, the greater the number of controlling components and their wiring. Here, it makes perfect sense to

think outside the box: Industrial machine tools have always

required regularly recurring control operations to be carried out. In 1969,

the programmable logic controller (PLC) was invented for this purpose, a

switching mechanism programmable via groups of switches or later digitally,

which can switch functions of the connected machine on and off depending on

the activation of contacts in the machine. One of the inventors "...

resisted the name computer. He saw this as endangering acceptance among the

control specialists who had been working up to that time." I regard PLC

in this form as, in the effect, nothing else but a highly complex relay

switchgear, and thus to be in my sense and

thus in the sense of my group and this homepage. I would now like to return to the

differences between the so-called “digital” and the so-called “analog” model

railroad. The operating principle of the

digital model railroad: Theoretically, there are only two

lines leading to the track and, thus, to all signals and turnouts on the

digital Märklin model railroad. (In real life, there are several more...). A command, similar to a Morse code,

is sent to this pair of wires. All decoders read it. The message starts with the

name of the unit which the message is addressed to. Turnouts and signals with

other names ignore the message; the one turnout that is addressed executes

the command that then follows. So this is completely different from

an conventional installation, where each turnout and

each signal is connected to the control device by a whole bundle of wires,

and each function has its own command wire, also when using a PLC! I am in the planning stages of my

next layout. So far, I see no reason to entrust an electronic brain with

tasks instead of the hardwired relays. However, if you include speed control of the trains, the circuit complexity

becomes immense. That's what we're looking at now: With digital train control, it is

the same as with the turnouts: first the address, then the command. With

locomotives, there can be up to 32 (or more) functions in addition to speed

control. This is of course impossible by electromechanical means – at least

in the locomotive. Märklin introduced a pulse width

control with ~ 200 Hz to the market as early as 1978 in the form of the 6699

“power pack with electronic control for slow speed driving”. This made -

hand-guided - extremely slow driving and gentle starting and braking possible

- by electronic means. The very short switching pulse also made it possible

to minimize the leap when switching the direction of locomotives of the 800

series. In 1983, the 6600 version, which was

expanded to include a shuttle train control system, was released. Here also

an automatic load control, which should keep the speed constant uphill and

downhill, was integrated. Although one is inclined to think of digitally

control with these two devices, they belong to the conventional control and

are thus in my sense and thus in the sense of my group and this homepage. The described speed controls always

require the regulating hand. What would an automatic speed control with

electromechanical control have to look like? A train needs the following

different voltages during its way across the layout:

There are a number of ways to

provide these different voltages. Ultimately, they have to be made available

at the right time at the right track section. This can be achieved with

relays or - for a larger number of trains – better with a PLC, or with a PC

with switching interface. These only replace the manual operation, which

would be impossible to manage. – However, in the meantime I have found a

concept for an easily understandable relay control; it should work without a

computer after all... For the acceleration and

deceleration processes, there are ready-made components based on

semiconductors or instructions for home-made circuits, switched on via the

control system. This, too, I consider to be in my sense and thus in the sense of my group

and this homepage. Sounds can be played from

loudspeakers connected to a sound unit at the specific locations of the

layout, and triggered by the locomotive or the controller. Moving sounds can

be controlled as stereo or quadraphonic events (see Miniatur Wunderland at All this is one of the basic ideas

for the founding of my group and thus also of this homepage. Everything (?) that can be done digitally can

somehow also be achieved by "analog", no, conventional means... |

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

state: 21.06.2023 18:10 |

|

Contact:

Mail |