|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

B: Special knowledge

about tracks B3: Märklin “Modellgleis” (model track) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Modellgleis? What is that? The German „Modellgleis“

means „model track“. But the „Märklin-Modellgleis“ is really something

special. There is a reason, that

so many people pay about 45 € / 53 $ / 40 £ for a 65 years old turnout. Let’s look, what is so special and whether it is

worth to go for a hunt… Vocabulary: How it started… Until 1953 Märklin

delivered only tinplate tracks with a third center rail as conductor. Then Märklin presented a

new track, the „Modellgleis“, a quantum leap in track construction. Unter the following link you find a

very good German description, that I’m quoting here: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The „Modellgleis

3900“, made as metal-plasic-mixed construction.

1953

the Märklin „Modellgleis“ saw the light of day. The

development of the track, probably espacially the plasic-injection molding

technology, took place in collaboration with the french model railway

producer Vollon et Brun, who offered similar tracks as the Märklin standart

track on the french as well the international market. The

„Modellgleis“ represented a technical revolution in four ways: 1. The center conductor as

continuous third rail had been replaced by point contacts for the first time. 2. The Track was made as

metal-plastic-mixed construction. The

plasic sleepers were embedded in the metal bedding. The balast bed is mottled

beige-brown, embossed and painted. The sleepers are colored black. 3. The geometry of the previous

track was abandoned and in particular

two new, large radii, R4 and R5 compared with later systems, have been

introduced. 4. The turnouts of this system

with a large radius and a flat branch angle of approx. 17 degrees were

designed as slim turnouts. The 17 degrees correspond to ¾ of the 22.5 degrees

standard curve track of the „Modellgleis“ system.

„Modellgleis 3900“

Comparsion of

„Modellgleis 3900“ and „M-track 5100“.

Comparsion of „Modellgleis 3900“ and

„M-track 5100“, bedding underside. Both

the enormous space requirements of this track geometry at a time when small

„table top" tracks were still the measure of all things, as well as the

significantly higher price compared to the standard track still included in

the range (Price example 1955: Two and a half times as expensive, -, 60

pfennigs the straight 3600 standard track at 1.50 marks for the straight 3900

„Modellgleis“, which was due to the complex production and patent / license

costs to Vollon et Brun as a development partner) made the „Modellgleis“

unsuccessful, so it was disappeared from the catalog in 1957. Only in the

present is it a sought-after, rare and high-priced product on the collector's

market. Quote

from the 1955 catalog for the „Modellgleis“: „These „Modellgleise“ combine

the advantages of the 3-rail track with the model appearance of the 2-rail

track. As in the 1:1 railway, the sleepers are separate parts, separate from

the rest of the rail bed. Realistic track layout design by parallel circle.

[...] The 3600 track sections can be used together with the 3900

„Modellgleis“ sections without any difficulty." The

system comprised 2 radii (R4 and R5), straight tracks, contact tracks, the

slim, electrically driven turnouts and a matching crossing. As in the later

C-Track system, the slender turnouts are combined with fitting pieces for the

corresponding position depending on the track plan. The embankment of these

„Modellgleis” fittings is accordingly not at a 45 degree angle in the contact

areas, but rather straight. The

previous 180 mm geometry was abandoned and the standard length of the

straight track is 224 mm for the „Modellgleis”. The curved tracks were

implemented as 22.5 degree pieces, so that 16 track pieces form a full

circle. A

connection with the standard tracks is possible and was expressly mentioned

in the catalog.

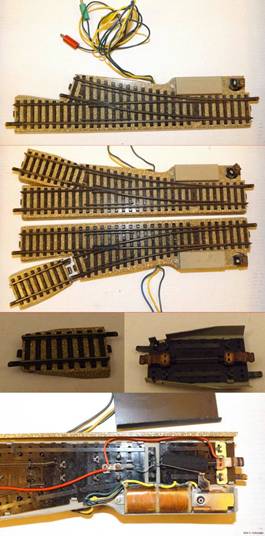

„Modellgleis“ electric turnout 3900 MW. The

electric turnouts had an illuminated turnout lantern. Despite the relatively

short production period, parallel to the development of the „M-Track

5100-5200”, modifications of the turnout lanterns and turnout drives can be

found in the image documents for the „Modellgleis”. The

switch technology changes in parallel from that of the 3600 track to that of

the 5100 track, although the first switch lanterns of the „Modellgleis” were

significantly smaller than those of the 3600 track. This

range is referred to as „Modellgleis”

or „Modellgleis 3900”. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Quote End What

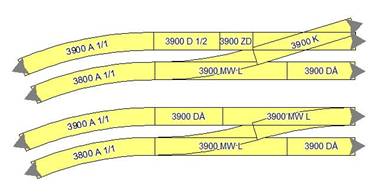

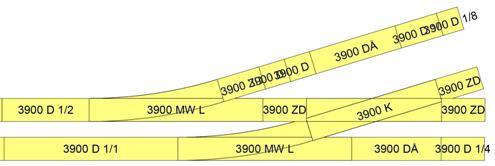

pieces of track were there? Note: The table below the quoted report is

difficult to read in this reproduction, contains errors and is incomplete.

Therefore I write the table of the tracks available at the time myself. First we look into the

catalog of 1953: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

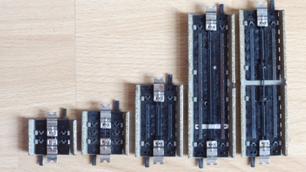

Straight pieces of

track

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note: The straight supplementary track section is

referred to as 3900 DÅ in the track planning program SCARM, which I’m

using for the graphics here. The visible difference

between 3900 DE and 3900 D 1/2 is a 3 mm wider sleeper spacing on half of the

3 mm longer track section. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The benefits of the

complementary track section can be seen in the following track plans:

At a track connection

with two turnouts or a turnout and an crossing, it ensures that both tracks

end in one line. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Track curves

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Curves 3800 and 3900 are significantly larger than those of the M

track. The curve angle of the

1/1 curve is 22.5°, therefore 8 pieces of track are required for a

semicircle. The following track plan

shows the proportions. For illustration I have

put a couple of short four-axle passenger wagons on top. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The article cited above

speaks of R4 and R5. I am talking more about R3+ and R4+. Next the comparison with

the C-Track (green) and the K-Track (blue): |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Turnouts, Crossing and accessories

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The turnouts have the same radius (585 mm) as the curves with 3900

numbers, but only 3/4 of this arc angle of the 1/1 curve (which is 22.5°).

The branch ends so early that no normal section of track will fit. There are 3 additional

pieces of track available for this purpose: The left turnout can be

supplemented with the additional track section ZL to 22.5° and the right with

ZR. You can also use the

original angle of 16.875° with the additional straight track section ZD. And - this is

interesting - you can put a left additional track section on the right

turnout or a right one on the left turnout. This reduces the turnout angle to

11.25°. However, there is a very slight winding movement of the train when

driving over it. If you attach the

opposite curve directly to the switch or the additional track section without

an intermediate straight piece of track, these track distances (in mm) result

with the various combinations: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The crossing is used to

cross the neighboring track, for example at a branch or a siding. That's why

it has the same angle as the turnouts.

Here you can see the restriction imposed

by the compulsory use of the additional track sections: An additional piece of track must

always be inserted at the branch of the turnout and at the track ends of the

crossing.

TIP: With manual dexterity you can certainly also adapt the

bedding of other tracks. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Bumper It was the first time that a bumper

of this design appeared in the Märklin range. The basis was the straight 1/4 track

section 3900 D 1/4. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

And now let's take a

closer look ... |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

First we consider the complex basic

construction. The sheet metal ballast bed has an

opening for each sleeper. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The sleepers are part of a plastic

insert that is held in the bed from below with bent sheet metal tabs. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The 1/1 track sections (straight as

well as arches) have 2 inserts, each with half the track section length. This

will probably have production-related reasons and stock-economy reasons. The

1/1 and 1/2 track sections have the same inserts.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The straight 1/4, 1/7 and 1/8 track

sections have their own inserts. The supplementary track section 3900 DE has

2 inserts of the 1/4 track section. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The hollow profile rails (the

switches have full profile) lie on top of the sleepers. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

They are held in place by bent metal

noses that protrude from below through the sleepers. The noses are part of a

continuous metal band that lies on the underside of the insert. Each rail is isolated from the other

and from the track structure. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The rails are not attached to the last

sleeper because there is the connecting strap on one rail and the space for

the connecting strap of the rail to be attached to the other. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A stronger claw is attached to the

penultimate sill, presumably to absorb the increased forces when sticking together. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

With many pieces of track there is a

metal bridge between the rails, so that both rails are then electrically

connected. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The bridge is not set to all track

sections. There are two generations - I will come back to this when

describing the center conductor. The first generation have no bridge with the

exception of the connecting and contact tracks, the second generation not

always. With arches of the 3800 form, I sometimes find the bridge at the

other end. The 1/4 (straight tracks and curved

tracks), 1/7 and 1/8 track sections as well as the straight supplementary

track sections 3900 DE and the additional track sections 3900 ZD, ZL and ZR

generally do not have a bridge. This bridge can be found in the C Track today. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

On the terminal track sections, the

bridge is the connection point for the earth cable. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There are bridges at both ends of

the contact track. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A rail is cut in two places and the

metal band is parallel to it on the underside. This creates a piece of rail

that has no electrical connection to the rest of the track. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In the middle of the insulated rail

section, a connector with 2 sockets is inserted into the track. The sockets

are connected to the insulated rail section. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

TIP: You can also turn a normal piece of track into a piece of contact

track: You cut through the bridge, if it is present at all. Then you solder a

connection line to one of the rails and replace the connecting brackets on this

rail and on the subsequent rail with insulating rail connectors that

are available from Fleischmann (No. 6403 or 6433) and Roco (No. 42611). Done! |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

As mentioned, there are two

generations of the „Modellgleis“. The primary characteristic is the

type of center conductor connecting tongue. The first generation has small

copper tongues, the second generation wide and slightly longer nickel-plated

tongues. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Note: When

assembling our M-rails, you can first bring the middle conductor tongues into

the desired overlap before threading the rail brackets. The copper tongues

of the „Modellgleise“ are so short and the rail brackets so long that you

first have to thread in the rail brackets and then you can only determine the

top-bottom position of the copper tongues with problems. The nickel-plated

tongues of the second generation are longer and significantly more stable

than the copper tongues. This means that they can

be plugged together as we are used to. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

If you visually

compare the M-rails with the „Modellgleis“, you will notice that the point

contacts of the „Modellgleis“ are much less conspicuous. The sleepers are

nicer, the surface uninterrupted. The optics of the M-track between 1956 and

1981 (center) were significantly worse. Only the version from 1982 (above)

came closer to the appearance of the „Modellgleis“. That is why I only use the upper version in the

visible area and „Modellgleise“ or my M-Flex-track in the arches. The central conductor is a steel

comb that extends in one piece from the first to the last sleeper. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In

relation to the plastic insert or the two inserts, the second and penultimate

puko noses are missing. At these points Puko inserts are let into the

sleepers from above, which have lugs on the underside with which the Puko

comb is attached. Track sections with two plastic inserts therefore have 4

attachments of the Puko comb, track sections with one plastic insert 2

attachments. The

central conductor connecting tongues are fastened together with the central

conductor comb on the central conductor fastenings at the ends of the track

section, i.e. on the second or penultimate sleeper. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

An

interesting form detail of the arches: The

sheet metal track body has a 2 mm wide fold on the lower edges, on which the

track rests on the table. We know that from the older M-tracks. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The

difference to the M-rails is that this fold has gaps. This makes it possible

to raise the outer edge of the arch by this 2 mm with little effort, to

„exaggerate" the arch by bending the fold back again. I

found the track shown in a bundle. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Now let's take a

closer look at the turnouts: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

As mentioned, the turnouts have

solid profile rails. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The radius of the branch is 585 mm,

the curve angle is 3/4 of the normal „Modellgleis“ curve. It doesn't get any

shorter than this. This turnout design was only taken up again by Märklin in

1975 with the M-track turnouts 5137 to 39. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The guard rails (check rails) are

made of metal, very solid and, with a distance of approx. 2 mm from the stock

rail, significantly more effective than those on the M-track turnouts. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The turnout lantern is almost

identical to that of the M-track turnouts of that time. The cover of the solenoids is a

little ... unattractive. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The construction of the turnout blades

deserves special attention: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Both tongues have their own pivot

bearings. This type of construction is still used today in German tram

turnouts. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The tongues are prototypically

slimmed towards the end, the stock rails have recesses to accommodate the

tongues. The tongues are moved by a slide in

the middle of the tongues where there is no sleeper. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The shortness of the branching track

requires special adapters. The elaborate interior of the turnout prevents

such a simple solution as was chosen for the M-track turnouts 5137 to 39

(almost every track section fits there). |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Two turnouts fit together with their

branching legs. The crossing of the „Modellgleis“ system also fits directly

to the turnout. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

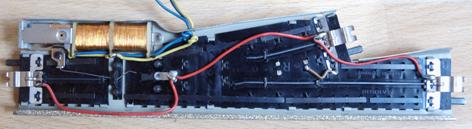

We now look at the turnout from

below: |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The drive is covered, as you are

used to with M-track turnouts.

The center conductors are mounted in

4 parts in the plastic insert and connected with a red wire. The metal contact area around the

frog is connected with a brown wire. The above-mentioned slide for moving

the tongues is moved by a simple rigid wire. The shape of the kinked wire

creates the movement of the slide. The elasticity of the wire allows the

switch to be cut open.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

A simple kinked wire, pushed straight through a hole

... ingeniously simple. No spring that

can wear out, break or get lost. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Conclusion: If one

observes the market with patience and common sense, the „Modellgleise“ can be

acquired at prices that have to be paid for new C‑track sections. Anyone who is impatient or wants unmarked pieces can

pay many times more. The „Modellgleise“ are fully compatible with the M

track system, but noticeably more beautiful than this. Turnouts and curves are unrivaled in the M-Track

system. That is why they are the first choice for me in the visible system

area. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

state: 03.10.2023 11:06 |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Contact:

Mail |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||