|

|

||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

||||

|

A: The very first

basic knowlege about conventionally controlled Märklin H0 model railways A11:

Maintenance – clean, lubricate,

replace |

||||

|

I

know of two detailed German brochures from Märklin on this subject for

conventional traction units: (click on the picture to open) |

||||

|

I'll

add my two cents here: Cleaning |

||||

|

Dust and grease/oil together form an insulating layer that settles on

the rails and on the running surfaces of the wheels (picture 1). Regularly vacuum dust from the tracks and degrease with a cleaning

agent. There are vacuum cleaner wagons from several manufacturers. The steam and cleaning oil SR24 and light petrol such as lighter fuel

and petroleum ether as well as isopropanol / isopropyl alcohol are suitable

for degreasing. Cleaning the wheel treads is tedious but rewarding. |

|

|||

|

The locomotive wheels must be kept clean as a matter of priority to

ensure trouble-free operation. The wheels of trailers with sliders must also be cleaned so that the

train lighting functions as uninterruptedly as possible. A glass fiber brush is suitable for cleaning, with the disadvantage of

the broken glass fibers which are unpleasant in your skin. Sanding blocks are available in various grit sizes. (picture 2) Some people use a sharp screwdriver blade or knife to scrape off the

layer. For wagon axles there is a cleaning device from the Lux company. The rails should never be sanded, because the dirt gets stuck in the

grooves that are created. If sanding is unavoidable, then smooth with the finest abrasive

afterwards and then polish. A blue ink eraser is also recommended. Isoprpanol / isopropyl alcohol is recommended for cleaning the rails. The centre conductor is kept bright by the grinders during regular

operation. After a longer period of non-use, a light oxide layer can form. Basic cleaning of second-hand locomotives Some people are too good at lubricating their locomotives. If you then take over a little treasure from them, it often makes sense

to carry out a basic cleaning. Even brand-new locomotives that have been in their box or in the display

case for years can be completely gummed up. If it hardly/never wants to run, just hums, then it is due for a

thorough cleaning. CAUTION: The cleaning methods practised are quite different:

For the last two procedures, it makes sense to remove the housing so

that the cleaning agent can reach everywhere - more disassembly is not

necessary. The electronics must be protected from the detergents, so do not immerse

them in the bath. For the last method, which I use myself, the above-mentioned SR-24 or

lighter fluid or petroleum ether is suitable as a cleaning bath. The latter,

however, is a fire hazard! An exposure time of 30 minutes can be enough to loosen the coatings. The insulating tape around the coil of the direction switch will come

off. Traction tyres become grippy again. You do not have to dismantle them. In SR-24, you can even run the engine to flush out the dirt from the

last corners. |

||||

|

To do this, connect test leads with crocodile clips to the slider (red

transformer connection) and e.g. to the buffer (brown transformer

connection). SR-24 is not conductive, so there is no short circuit. I show a video of this. |

||||

|

SR-24 is harmful to health, I show the German safety

data sheet. It is therefore surprising that

it is permissible to vaporise it in "children's toys". |

||||

|

Because of the possible fire/explosion hazard, I advise against running

it in petrol. After the bath, let the locomotive running gear drip off. The cleaning fluid remains in the spoke wheels and joints, so it makes

sense to blow off all sides of the locomotive. Then let it dry for a few hours. The bearings are now dry, so now it's time for lubrication.... Lubricating All bearings on Märklin models are slide bearings. These occasionally need "a trace" of oil. A trace means considerably less than a drop. Rather a light wetting, a

touch.... It is strongly recommended to use oil that is free of resin and acid. But even Märklin itself used oil in the 80s, which has gummed up over

the years. The recommendations of practitioners from the forums are:

Lubrication points: |

||||

|

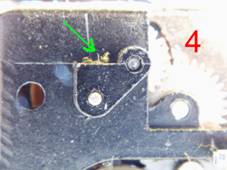

Armature shaft When the locomotive starts to squeal, it is high time. On engines with disc collectors, there are lubrication pockets with foam

rubber filling above the armature shaft as a depot for the oil. (picture 3

and picture 4). |

|

|||

|

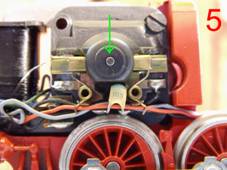

Motors with a drum collector have no lubrication pockets. Tiny drops are applied to the shaft ends there. (picture 5 and picture

6). |

|

|||

|

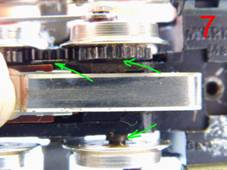

Axles Locomotive axles have internal bearings, they are inserted through the

frame. A trace of oil to the bearing point. (picture 7) |

|

|||

|

Axles of wagons are mounted on the outside, in needle bearings or tip

bearings. Opinions differ: clean and dry or lightly grease. Graphite is probably best here, because it does not attract dust. Gears and gears should be lightly greased rather than oiled. |

||||

|

The slider of the Reverse Unit should not be lubricated, at most with

graphite. (picture 8) |

|

|||

|

Wear parts A "wear part" is a component that is worn out under intended

use, worn out and then replaced. Exploded views and spare parts lists for traction units Exploded views and spare parts lists for accessories A list of spare parts for Märklin H0

locomotives from a supplier |

||||

|

Slider on the centre conductor (Picture 9) When grooves have formed and/or the silver coating has worn

through and the brass core is visible, it is time for replacement. The life of the sliders can be increased by making sure that the slider

is not bent. |

|

|||

|

The slider in the example picture is bent and therefore shows uneven

wear. The "brushes" on the motor collector On Märklin motors, two contacts are transferred to the armature (the

rotating part of the motor). The contact surfaces on the armature are called collector. The parts rubbing on the collector are called brushes. There are two collector forms: |

||||

|

1. the motor with disc collector (picture 10): Märklin no. 60 030

for the pair of brushes, consisting of a coiled copper net and a cylindrical

carbon with a slot. The retaining springs are shaped to fit: angled on the left for the hole

in the copper coil, straight on the right for the groove in the carbon. |

|

|||

|

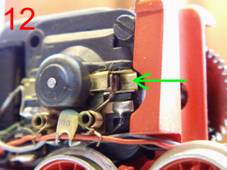

2. the motor with drum collector (pictures 11 and 12): Märklin No.

60 146 for the pair of brushes, consisting of two square carbon pins with a

groove at one end. The retaining springs belong in the groove. |

|

|||

|

Traction tyres Märklin locomotives have at least one traction tyre. You can see where a traction tyre belongs by the groove in the wheel

tread. Without a traction tyre, the friction between the wheel and the rail is

very low. With a heavy locomotive and light wagons, this can still work on

horizontal track, but even tight curves or slight inclines can end the journey. Märklin offers traction tyres in 4 sizes as bags of 10:

The adhesive tyre is slightly smaller before mounting so that it sits

with tension on the wheel and does not slip. Over time, traction tyres become harder and more brittle. As a result, they grip increasingly poorly and can tear off. In the past, there were other sizes. For example, on the old E18 (3023/3024) the order number for the

adhesive tyres is 7148. For the new model of the E18, the order no. is 7153, so they should also

fit the old E18. If you search Ebay with these numbers, you will also find very cheap

imitations. They also work. There is also liquid rubber that you can fill into the groove with the

appropriate manual skills. Opinions on this vary widely... On my steam locomotives, the last driven axle almost always has 2

traction tyres. Exceptions:

Locomotives with bogies usually have 4 traction tyres on the driven

axles, even the 6-axle ones. The small diesel locomotives have 2 traction tyres on the rearmost axle. |

||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

||||

|

state: 10.10.2023 20:01 |

||||

|

Contact:

Mail |

||||