|

|

|

|||||||||||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

|||||||||||||

|

A: The very first

basic knowlege about conventionally controlled Märklin H0 model railways A4: White – blue – orange – |

|

|||||||||||||

|

ATTENTION: Safety-relevant topic!!! The topic of the old Märklin

transformers is a recurring one.

The

white Märklin transformers no. 6647, 66470, 66471 are recommended in the area

of power supply with 230V. But other mothers have beautyful

daughters too… First, let’s take a look at the

Märklin transformers since 1949. Only transformers for 220V or 230V

and for the German market are listed. A click on a transformer image shows

the catalog sheet of the respective year. |

|

|||||||||||||

|

|

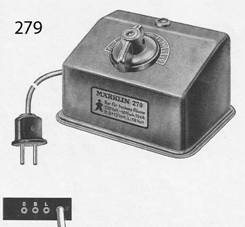

10VA |

16VA |

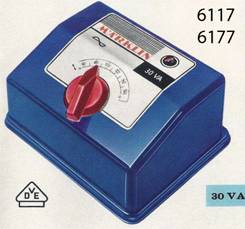

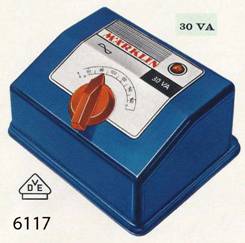

30VA |

|||||||||||

|

blue sheet metal housing |

||||||||||||||

|

1949 |

|

|||||||||||||

|

At that time, the round plug, as

shown in the pictures, was the „normal appliance plug“. |

||||||||||||||

|

1952 |

|

(15VA) |

||||||||||||

|

1953 |

|

|||||||||||||

|

From 1957 onwards, all Märklin

products were given new numbers with unchanged design. In the 1950s, the SCHUKO system gradually

replaced the previous normal round plugs and flat sockets in |

||||||||||||||

|

1957 |

|

|||||||||||||

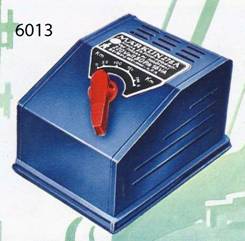

|

1960 |

||||||||||||||

|

From 1960 the contour plug with the

shape of a SCHUKO plug became standard in Märklin assured in the catalog:

“This transformer complies with the lastest official

regulations.” or “…latest regulations of the VDE”, from 1961 on: “The

transformer … has been tested and approved by the VDE.” |

||||||||||||||

|

1962 |

|

|||||||||||||

|

1965 |

||||||||||||||

|

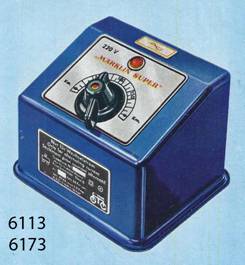

1968 |

||||||||||||||

|

From 1968 onwards, the mains cables

were fitted with the “unified plug”, toda called the EURO plug. The two Primex transformers also date

from this time. |

||||||||||||||

|

|

identical

in construction 6413 |

|

identical

in construction6117 |

|||||||||||

|

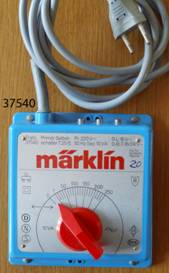

blue plastic housing, EURO plug |

||||||||||||||

|

1973 |

still sheet metal housing |

|||||||||||||

|

1975 |

In 1975, the sheet metal

transformer 6511 was still listed in the German catalog without picture. |

|||||||||||||

|

From 1992 onwards, the plastic

transformers were fitted with safety terminals instead of sockets at the

output. |

||||||||||||||

|

1992 |

|

|||||||||||||

|

|

white plastic housing 32VA |

|||||||||||||

|

1994 |

Only with the Alpha

programm |

|

||||||||||||

|

1996 |

|

|

||||||||||||

|

Numbers

become 5 digits. |

||||||||||||||

|

2011 |

|

|

||||||||||||

|

A power switch is added. |

||||||||||||||

|

2016 |

|

|

||||||||||||

|

Now we examine why oder transformers

should be used with caution or better not. The problems with the older

transformers are: 1st: the current electrical regulations 2nd: the ageing of the insulating

materials in the transformer and the connection cable 3rd: the increase of the mains voltage

from 220V ±22V to 230V ±23V since 1987/2009 (see Wikipedia) To 1st: The applicable electrical regulations Some applicable regulations

contradict the operation of the old sheet metal transformers. Unacceptable

insulating materials, even if they were new, construction features of the

components. The transformers up to 1959 in the

table lack protective insulation. Please do not use them any more! I disposed

of mine. The protective insulation can be

recognised by the symbol on the type plate: a square within a square. The

transformers from 1960 onwards therefore have protective insulation. All transformers with a double

square in the type plate should be safe, but you can only be completely sure

if you have the transformer checked by a recognised specialist company,

especially for the condition of the protective insulation. Make sure that the supply cable is

intact and free of cracks or brittle changes. The transformers are not suitable or

approved for damp rooms. This means that some basements are

unsuitable for operation. For further, more in-depth

explanation, I bring here the report of a member of my Facebook group, the

master electrician Dieter Hammerl: The

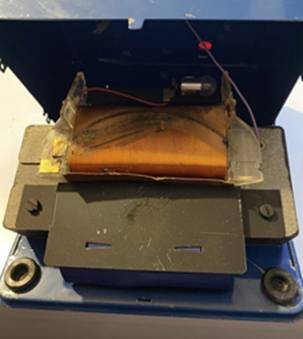

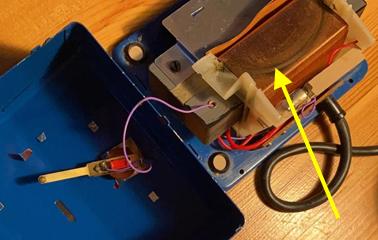

tale of the blue metal transformer with the red rotary knob, which is

dangerous. To put an end to this discussion, I took the liberty of scrapping one

of my transformers today. Since it is now open, it has lost its operating licence. I am a master electrician and could close this transformer again so

that it could be used, but I won't do it; who knows what else it is good for.

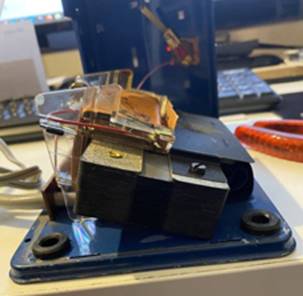

The first picture shows which kind of transformer it is. |

|

|||||||||||||

|

The second picture shows the connection side with the symbols. |

|

|||||||||||||

|

On the third and fourth picture you can see the transformer assembly. |

|

|||||||||||||

|

|

|

|||||||||||||

|

|

|

|||||||||||||

|

The sixth picture shows the protective insulation that prevents an

active conductor (wire) from touching the housing. |

|

|||||||||||||

|

In the case of the transformer shown, mechanical precautions have been

taken to ensure that no conductive connection can occur between an active

conductor (230V) and the housing. However, this also presupposes that the

transformer is still in the original condition in which it was delivered from

the factory. As soon as the transformer shows deformations or changes in

colour or massive rusting or the connection cable is porous and the

insulation is possibly already crumbling or partially missing, the transformer

has lost its operating licence and must be disposed of. The transformer

should also be disposed of if the connection cable has been replaced and

there is no new safety certificate on the transformer issued by a specialist

electrical company. The statements only refer to the electrical operational safety. I cannot rule out the possibility that this transformer will fry

decoders or send electronic components to nirvana heaven with its switching

voltage, as I only drive conventionally.

The last picture also shows a blue transformer, but with a plastic

housing. I advise against using even older transformers, as they have reached

their end of life. In general, if you don't have a good feeling about using the transformer

described or another transformer with a metal housing because you don't know

whether it has been operated in accordance with the regulations, dispose of

the transformer. End of quote To 2nd: The ageing

of the insulating materials in the transformer and the connecting cable. Many a person has had an old cable

crumble in their hands. Replacing the supply cable requires opening the

riveted housing, which can lead to uncontrollable new damage inside. The

effort and the new risk are not worth it. The old blue Märklin transformers

with sheet metal housings are many decades old and meanwhile "End of

Life", are no longer considered safe to operate. And another quote from Dieter

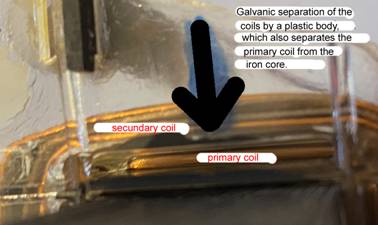

Hammerl: For all

those who think that transformers with a blue housing and a red regulator

could lead to a fatal electric shock. As I have written in other posts, these transformers are

"protective insulated" and produce a "protective extra-low

voltage" suitable for toys. "Protective insulated" means that no active wire or active

component (230 V) can touch the metal housing. "Protective extra-low voltage" means that the windings

(coils) are galvanically separated and also cannot touch the transformer

core. It also means that no "autotransformer" may be used. By BillC - Own work, CC BY-SA 3.0,

https://commons.wikimedia.org/w/index.php?curid=524847 What is

an "autotransformer"? (see Wikipedia) (Graphic

by BillC - Own work, CC BY-SA 3.0)

Autotransformers must not be used for toys! But if you want to do something extra for your safety, you can have the

circuit to which the transformers are connected by means of a Europlug (the

flat plug without a protective contact) equipped with its own

residual-current device (RCD). This is a change to the sub-distribution and

must be carried out by a recognised electrical specialist, i.e. your favourite

electrical installation company. What

does this residual-current device (RCD) do? If, contrary to expectations, the connection between an active

component and the housing, which is often invoked, should occur, you will receive

an electric shock from the transformer when touching the housing. However,

this is not dangerous because the residual current circuit breaker ensures

that a maximum voltage of less than 50 V can build up across the resistor,

i.e. the connection between you and the transformer housing and your contact

with the ground. And 50 V is not dangerous for you. If it is not possible for you to have an additional residual-current

device (RCD) installed in the distribution board, ask your trusted electrical

installation company to build you a small distribution board from an

insulated housing. He will provide the supply line with a protective contact

plug, which you can then plug into your socket and at the other end he will

build a socket strip with 10 or more sockets. Please do not plug any other multiple sockets into the sockets here,

otherwise you will lose your insurance cover. According to the recognised

rules of technology and the rules of property insurers, it is not permitted

to plug other multiple sockets into a multiple socket. |

|

|||||||||||||

|

So: Not like that... (Photo: Herbert Otto,

Father's workroom) And in all confidence, which modeltrain specialist has not plugged at least

one multiple socket into a multiple socket? I would be much more concerned

about this than about whether an ACTIVE COMPONENT can touch the housing of a

device with protective insulation. The basis of this consideration is always the fact that the Märklin

transformers used are still in their original condition and the cable or

housing does not yet have any damage. Damages are among others:

etc. End of quote To 3rd: The

increase of the mains voltage from 220V ±22V to 230V ±23V since 1987/2009 (see Wikipedia) I would like to add some basic

knowledge to Dieter's comments: What is "the mains voltage": 230 volts AC with 50 hertz

frequency. Where does this apply? |

|

|||||||||||||

|

|

||||||||||||||

|

This was not always the case: Before 1987, when transformers were

manufactured for 220 volts, the mains voltage was allowed to be between 198 and

242 volts (220±22V) and that is what the transformers were built for. In a transitional period between

1987 and 2009, the mains voltage was allowed to be between 207 and 243.8

volts. However, the manufacturers knew which rule would come after that and built

their devices for the voltage range 207 to 253 volts (230±23V), which still

applies today. The actual mains voltage varies

regionally and also depends on the large consumers in the area. Where I live

in the northern outskirts of Physical principles

of the transformer 1st fact: A current-carrying

conductor causes a magnetic field in its surroundings (discovery by Hans

Christian Ørsted in 1820). (Wikipedia) If you take several insulated wires

in parallel and send current through them in the same direction, you get a

stronger magnetic field, the individual magnetic fields add up. If you wrap the insulated wire

around an iron core, you build an electromagnet. (This only works with iron

materials, with a few exceptions. Problem: iron can rust...) An electromagnet works with both

direct current and alternating current. With direct current, the iron core tends

to become permanently magnetic itself. This does not happen with alternating

current. 2nd Fact: When you move a

wire through a magnetic field, the magnetic field in the wire creates an

electric voltage. (Demonstrated: induction on the conductor

swing). Mind you, there has to be movement: If you feed an electromagnet with

alternating current, the magnetic field constantly builds up and degrades.

It's like moving the wire. So the wire may be stationary and yet a voltage is

generated in it.

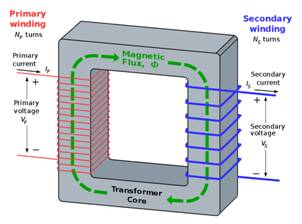

You expose a second coil to the

magnetic field of an electromagnet fed with alternating current, preferably

by winding both coils on a common iron core. Image by BillC at the

English-language Wikipedia, CC BY-SA 3.0,

https://commons.wikimedia.org/w/index.php?curid=27407689 The number of turns of the two coils

determines how the electrical voltage is transmitted: For example, if the number of turns

of the two coils is in a ratio of In the Märklin transformer there are

such two coils on a common iron core, optimised for the purpose of model

railway supply. The wires are insulated with only

very thin varnish. The number of windings is chosen in

such a way that 230V at the input results in 4V (in the case of the Märklin

transformer 6647, 66470, 66471) at the output. Why only 4V? As mentioned, the insulating lacquer

around the wires is only very thin. It is removed at certain points so that

the pick-up finger of the controller knob can touch the bare wires.

For the 25V switching voltage, there

are more turns, but they are not reached by the pick-up finger, but are

tapped directly and are available to the left of the 0-point. Once this is understood, it is clear

that a transformer built for 220V delivers somewhat higher output voltages at

230V mains voltage. In addition, there are manufacturing tolerances that

sometimes lead to values that cannot be fully explained. If you then add the changed

permissible tolerances, some old transformers can produce unpleasantly high

voltages at the limits of the permissible mains voltage. Unpleasant above all

for electronic components... If you operate a digitalised

traction unit in conventional mode and use a transformer that generates too

high a switching voltage, the electronics can be destroyed. The critical limit

is probably a good 30V; exact details are nowhere to be found. The ratio of input voltage to output

voltage is invariably determined by the number of winding turns. A transformer that was built for

220V ±22V and brought a switching voltage of 21.6V to 26.4V can today bring

up to 27.6V. That is the theory and does not

sound particularly dangerous. A modern transformer for 230±23V has

coils adapted to the voltage difference from 220V to 230V. Therefore it

should also deliver 21.6V to 26.4V. Now I have measured my most modern

Märklin transformer no. 6647. And lo and behold, at 253V input it

delivers max. 27.9V at the output. It should have delivered 26.4V,

which is 1.5V more. So far, no traction unit has been

damaged by this transformer. Therefore, I assume that approx. 28V

is still harmless. However, I have at least one member

in the group who has had decoders break down with a white transformer. I have measured all my transformers. The following ranking list refers to

the reversing switch voltage at 230V mains. |

|

|||||||||||||

|

rank |

brand |

no |

housing |

power |

for V |

reverse voltage at 230V mains |

|

|||||||

|

1 |

Märklin |

6647

|

plastic |

32VA |

230V |

25,2V |

|

|||||||

|

2 |

Titan)* |

808M

|

sheet

metal |

60VA |

220V |

25,5V |

|

|||||||

|

3 |

Märklin |

6631 |

plastic |

30VA |

230V |

26,2V |

|

|||||||

|

4 |

Titan)* |

109M

at |

sheet

metal / plastic)* |

60VA |

220V |

26,4V |

|

|||||||

|

5 |

Märklin |

6173 |

sheet

metal |

30VA |

220V |

27,2V |

|

|||||||

|

6 |

Märklin

|

6631 |

plastic |

30VA |

220V |

27,5V |

|

|||||||

|

7 |

Märklin |

6413 |

sheet

metal |

10VA |

220V |

28,8V |

|

|||||||

|

8 |

Märklin |

6511 |

sheet

metal |

16VA |

220V |

29,0V |

|

|||||||

|

9 |

Primex |

6401 |

sheet

metal |

10VA |

220V |

29,1V |

|

|||||||

|

10 |

Märklin |

37540 |

plastic |

10VA |

220V |

30,1V |

|

|||||||

|

)* The Titan system transformers each consist of

a mother transformer and plug-in controller units. The worst is Märklin No. 37540 with

over 30V, at 253V mains up to 33V. Actually a modern transformer with

plastic housing. So the plastic housing is not a sign

I would not operate a digital

locomotive with this one, at most permanently set for a track without

switching. That's the recommendation for people

who can't throw anything away. Märklin writes about this (German): https://www.maerklin.de/fileadmin/media/service/faq/Technik-Tipp-207.pdf Light transformers |

|

|||||||||||||

|

1965 |

6210 |

|

||||||||||||

|

1968 |

6211 |

|

||||||||||||

|

1973 |

6611 |

|

||||||||||||

|

1974 |

6611 |

|

||||||||||||

|

1992 |

6002 |

|

||||||||||||

|

2005 |

60052 |

|

||||||||||||

|

I own only one 6611 in the design

from 1974. Furthermore I own a light

transformer from Piko, No. Z1 1756, giving and a light transformer from Roco,

No. 10725, giving |

|

|||||||||||||

|

The Prototype Märklin-H0-Knowledge Layout-Building Modelstock |

|

|||||||||||||

|

state: 07.01.2024 15:13 |

|

|||||||||||||

|

Contact:

Mail |

|

|||||||||||||